Over 15 Years’ Experience

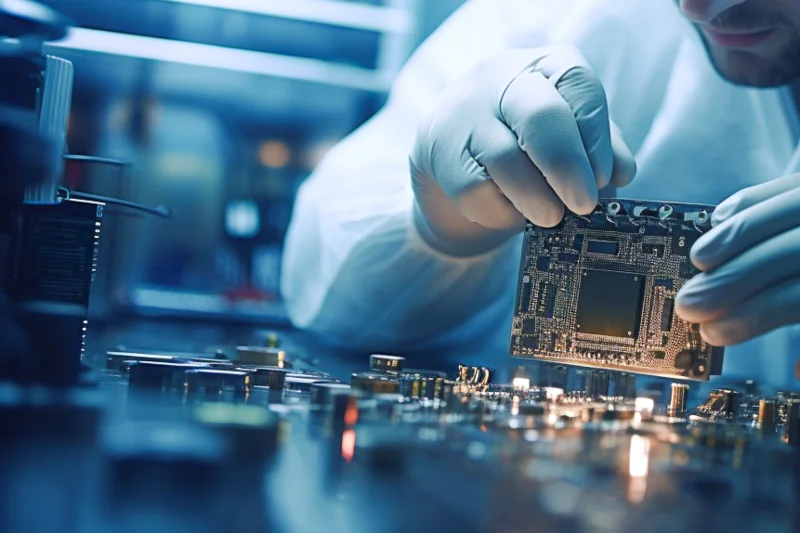

With over 15 years’ experience in the industry and as an experienced and reliable contract turnkey PCB assembly manufacturer, we offer a wide range of services to our customers in the Medical, Automotive, Telecommunications, and General industrial industries. Our expertise includes PCB fabrication, parts sourcing, and assembly. We specialize in both prototype and high volume full turnkey or partial PCB assembly.

![]()

PCB Assembly

| Feature | Capability |

| PCB Type | Rigid PCB,Flexible PCB,Rigid-flex PCB,Aluminum/metal core PCB |

| Large parts on both sides, BGA on both sides | Yes |

| Smallest Chip size | 201 |

| Min BGA and Micro BGA pitch and ball counts | 0.008 in. (0.2mm) pitch, ball count greater than 1000 |

| Min Leaded parts pitch | 0.008 in. (0.2 mm) |

| Max Parts size assembly by machine | 2.2 in. x 2.2 in. x 0.6 in. |

| Assembly surface mount connectors | Yes |

| Wire bonding | Yes |

| Cable Assemblies | Harnesses and Power Leads |

| LED | Yes (Manual assembly) |

| Resistor and capacitor networks | |

| Electrolytic capacitors | |

| Variable resistors and capacitors (pots) | |

| Sockets | |

| Wave soldering | Yes |

| Max PCB size | 14.5 in. x 19.5 in. |

| Min PCB Thickness | 0.02 |

| Fiducial Marks | Preferred but not required |

| PCB Finish: | SMOBC/HASL |

| Electrolytic gold | |

| Electroless gold | |

| Electroless silver | |

| Immersion gold | |

| Immersion tin | |

| OSP | |

| PCB Shape | Any |

| Panelized PCB | Tab routed |

| Breakaway tabs | |

| V-Scored | |

| Routed+ V scored | |

| Inspection | X-ray analysis |

| Microscope to 20X | |

| Rework | BGA removal and replacement station |

| SMT IR rework station | |

| Thru-hole rework station |

![]()

PCBA Services

A printed circuit board assembly (PCBA) facility provides a range of services related to the assembly and production of printed circuit boards (PCBs) and electronic components. These services may include:

- Turnkey Services: Offering full turnkey solutions, we handle all aspects of PCB assembly, including PCB, component sourcing, assembly, and testing, providing a convenient one-stop service.

- PCB Manufacturing and Procurement: Procure PCBs based on your design specifications.

- Component Sourcing and Procurement: With an extensive network of suppliers worldwide we can source and procure all the necessary components for your project.

- Design for Manufacturability (DFM) Review: We offer DFM reviews to optimize your PCB design for efficient and cost-effective assembly.

- Surface Mount (SMT) Assembly: Fully equipped with automated surface mount lines to support the most challenging design.

- Through-Hole Assembly: We have dedicated assembly lines to support designs that require more manual labor.

- Mixed-Technology Assembly: We have capabilities to support a mix of SMT/Through hole technology. Accommodating a wider range of component types and sizes.

- Prototype to Mass Production: Capacity to support small volume prototypes to mass assembly production.

- Testing and Quality Control: Ability to perform various tests and inspection such as Electrical, In-Circuit, Functional testing as well as X-Ray inspection for BGA packages adhering to IPC standards while handling with ESD protection through-out the manufacturing process.

- RoHS Compliance: Dedicated lines to support products that require RoHS compliance. Ensuring that assembled products do not contain harmful materials.

- Conformal Coating and Encapsulation: We have capability to apply conformal coatings and encapsulate PCBs and protect from environmental factors such as moisture, dust, and chemical exposure.

- Custom Packaging and Shipping: Ability to provide custom packaging if necessary.

- Reversed Engineering Services: With our extensive experience in the industry in certain cases we can reverse engineer old designs to extend the life of your products.