Your Trusted Metal Core PCB Manufacturer

GCS has extensive experience in manufacturing and developing new technologies in the MCPCB markets.

MCPCBs can be advantageous to use for their ability to integrate a dielectric polymer layer with a high thermal conductivity for a lower thermal resistance.

Metal core PCBs transfer heat 8 to 9 times faster than FR4 PCBs. MCPCB laminates dissipate heat, keeping heat generating components cooler which results in increased performance and life.

Request A Quote

![]()

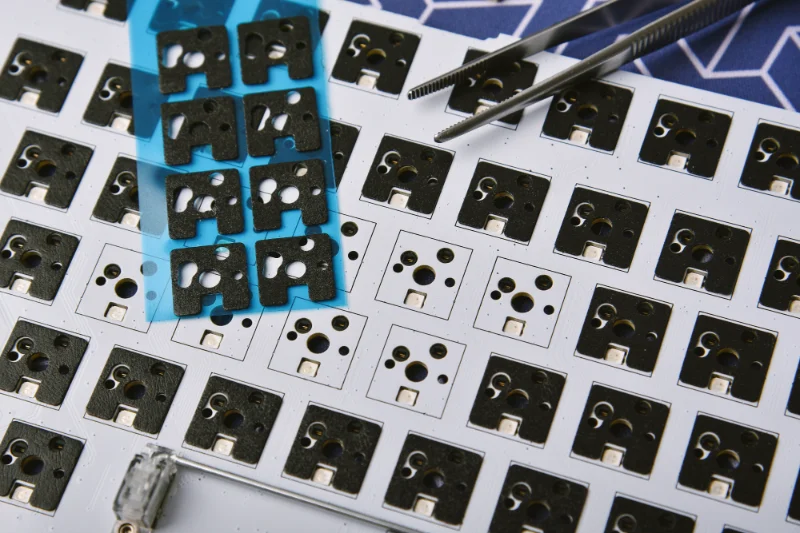

Metal Core PCB

| Feature | Capabilities |

| Layer Count | 1 – 10 Layers |

| Type | Aluminum Core, Copper Core, Sinkpad copper core. |

| IPC Standards | IPC Class 2, IPC Class 3 |

| Max Board Dimension | 24*64″(610*1625mm) |

| Min Board Thickness | 0.6mm |

| Max Board Thickness | 4.0mm |

| Conductor Thickness | 0.5oz – 10oz |

| Min Line Width/Line Space | 4/4mil (0.10/0.10mm) |

| Min Hole Diameter | 10mil (0.25mm) |

| Min Punch Hole Dia | 0.12″ (3.0mm) |

| Min Hole Spacing | 16mil (0.4mm) |

| Min PAD Ring(Single) | 3mil (0.075mm) |

| PTH Wall Thickness | Normal: 0.59mil (15um); HDI: 0.48mil (12um) |

| Min Solder PAD Dia | 14mil (0.35mm) |

| Min Soldermask Bridge | 8mil (0.20mm) |

| Solder Mask Colors | White, Black, Green, Red, Yellow (most common) others available. |

| Min BAG PAD Margin | 5mil (0.125mm) |

| PTH/NPTH Dia Tolerance | PTH: ±3 mil (0.075mm); NPTH: ±2mil (0.05mm) |

| Hole Position Deviation | ±3mil (0.075mm) |

| Outline Tolerance | CNC: ±6 mil (0.15mm); Die Punch: ±6 mil (0.1mm) |

| Max Aspect Ratio | 10:01 |

| Surface Treatment | ENIG, Flash Gold, Hard Gold Finger, Gold Plating(50mil), Gold finger, |

| Selected Gold Plating, ENEPIG, ENIPIG, HAL, HASL(LF), OSP, Silver Imm., Tin Imm |

![]()

Metal Core PCB Applications

Metal Core Printed Circuit Boards (MCPCBs) are specialized circuit boards that have a layer of thermally conductive material as their base, typically aluminum or copper, to enhance heat dissipation. These boards find applications in various industries and products where efficient thermal management is critical.

- LED Lighting: MCPCBs are extensively used in LED lighting systems, including high-power LED bulbs, automotive headlights, streetlights, and display screens. The superior thermal conductivity of the metal core helps dissipate the heat generated by LEDs, extending their lifespan and ensuring optimal performance.

- Power Supplies: MCPCBs are employed in power supply units, such as AC-DC converters, inverters, and voltage regulators. Efficient heat dissipation is crucial to maintaining the reliability and longevity of power electronics.

- Automotive Electronics: MCPCBs are used in various automotive applications, including engine control units (ECUs), LED headlights, brake controllers, and power management systems. The ability to handle high heat loads is essential in the automotive environment.

- Consumer Electronics: In devices like smartphones, tablets, and laptops, MCPCBs are used for thermal management to prevent overheating and ensure the efficient operation of processors, graphics cards, and other components.

- Industrial Equipment: MCPCBs are found in industrial control systems, motor drives, and automation equipment. These boards help maintain stable operation by dissipating heat effectively.

- Telecommunications: In telecommunications infrastructure, MCPCBs are used in high-power amplifiers, transceivers, and base stations, where heat management is essential for consistent performance.

- Medical Devices: Medical equipment like MRI machines, ultrasound devices, and X-ray systems use MCPCBs to dissipate the heat generated by sensitive electronic components, ensuring reliable and accurate operation.

- Aerospace: MCPCBs are used in avionics systems, radar systems and satellite communication equipment, where reliability and thermal performance are crucial.

- Renewable Energy: In solar inverters and wind power converters, MCPCBs help manage heat generated by power electronics in renewable energy systems, improving efficiency and longevity.

- Electric Vehicles (EVs): MCPCBs are used in EV power electronics, including battery management systems and motor drives, where efficient heat dissipation is vital for vehicle performance and safety.

- Audio Amplifiers: High-power audio amplifiers benefit from MCPCBs to dissipate heat generated during high-volume audio output, ensuring sound quality and system durability.

- Transportation: MCPCBs are used in transportation systems such as trains and trams for control and signaling systems, where reliability in varying temperature conditions is essential.

Get A Quote

Metal Core PCBs are chosen for their ability to dissipate heat efficiently, which extends the lifespan and reliability of electronic components and systems in applications where temperature control is a key consideration.

Request A Quote